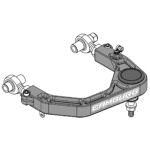

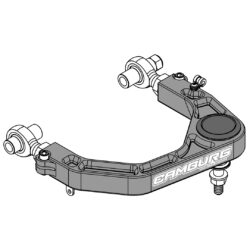

CAMBURG | KINETIK BILLET UCA | LC300 2022+

680.000 KWD

Countless hours were spent designing and refining these arms to the point where they met our high standards. CAD designing and machining gave us the ability to bring some new design elements and features to the table. We CNC machine these from aerospace quality 6061 billet aluminum, then send them out to be bead blasted, Type II anodized gun metal gray and have our Camburg logo laser etched.

Like our tubular arms we use a larger FK 1.25” uniball that has a PTFE liner for increased strength and mis-alignment for maximum useable wheel travel. Made in the USA these are far superior to the cheaper and smaller imports other companies use. Adapting the uniball to the spindle/knuckle is done using model specific spacers that match the factory taper precisely. These are machined from heat-treated stainless steel and are a one piece design for increased strength. No drilling or modifications are needed. The 1.25” uniball gives us the ability to run a larger bolt with a low profile press-on uniball cap to resist the elements.

Using larger and stronger FK 7/8” chromoly heim joints allows for additional camber and caster adjustment if needed. Using a heim joint also eliminates flexing/deflection under hard use and braking with zero binding when in use. Using AN/Mil-spec hardware we have a single pinch bolt and secondary jam nut to insure the heim is secure with the rigors of off-road use.

- NEW V2 design

- Increases usable wheel travel

- Corrects camber and caster

- Eliminates weak factory ball-joints

- CNC machined 6061 billet aluminum

- CAD/CAM engineered

- FK 7/8″ heim joints for adjustable camber and caster

- FK 1.25″ PTFE-lined uniballs pre-installed

- Anodized and laser etched

- All necessary hardware included and ready to install

- Made in the USA

- Designed for 1-3″ of lift

Quick Comparison

| CAMBURG | KINETIK BILLET UCA | LC300 2022+ remove | BDS | Upper Control Arm Kit | 2007-2018 GM 1500 remove | TOTAL CHAOS | UCA | TUNDRA 2007-2021 remove | CAMBURG | REAR CHROMOLY TUBULAR LOWER TRAILING ARM KIT | BRONCO 2021+ remove | TOTAL CHAOS | UCA | GM 1500 2019+ remove | CAMBURG | 1.25 PERFORMANCE UCA WITH COVER CAP | F150 2WD 4WD 2021+ remove | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Image |  |  |  |  |  |  | ||||||||||||||||||||||||

| Rating | ||||||||||||||||||||||||||||||

| Price | 680.000 KWD | 285.000 KWD | 335.000 KWD | 399.000 KWD | 350.000 KWD | 440.000 KWD | ||||||||||||||||||||||||

| Add to cart | ||||||||||||||||||||||||||||||

| Description | Countless hours were spent designing and refining these arms to the point where they met our high standards. CAD designing and machining gave us the ability to bring some new design elements and features to the table. We CNC machine these from aerospace quality 6061 billet aluminum, then send them out to be bead blasted, Type II anodized gun metal gray and have our Camburg logo laser etched.

Like our tubular arms we use a larger FK 1.25” uniball that has a PTFE liner for increased strength and mis-alignment for maximum useable wheel travel. Made in the USA these are far superior to the cheaper and smaller imports other companies use. Adapting the uniball to the spindle/knuckle is done using model specific spacers that match the factory taper precisely. These are machined from heat-treated stainless steel and are a one piece design for increased strength. No drilling or modifications are needed. The 1.25” uniball gives us the ability to run a larger bolt with a low profile press-on uniball cap to resist the elements.

Using larger and stronger FK 7/8” chromoly heim joints allows for additional camber and caster adjustment if needed. Using a heim joint also eliminates flexing/deflection under hard use and braking with zero binding when in use. Using AN/Mil-spec hardware we have a single pinch bolt and secondary jam nut to insure the heim is secure with the rigors of off-road use.

| These BDS Suspension BDS121151 Upper Control Arms (UCAs) for the Chevy Silverado 2007 thru 2013 models are designed for improved strength, added suspension travel and elimination of ball joint binding on leveled and lifted Silverado 1500 vehicles. Built from high strength 1.5" OD x .120-wall tubing and fully welded for strength and durability. They use an indexed ball joint cup to correct the ball joint positioning for when used with leveling or full lift kits. Factory style durometer-specific rubber bushings are used for longer lasting durability (more durable than poly bushings). Featuring premium quality MOOG ball joints for smooth, quiet operation and superior corrosion resistance to arms that feature uni-balls, poly bushings or heims. |

| PRODUCT OVERVIEW: Camburg's tubular uniball series trailing arms take your Ford Bronco to the next level. Camburg uses thick walled 4130 chromoly tubing for greater strength and impact resistance when hitting the trails. Camburg's trailing arms increase ground clearance over stock so you won’t get hung up on rocks and potentially damage the frame or get stuck. With FK 1″ uniball bearing pivots front and rear, these precision bearings allow for zero flex or binding with maximum articulation and wheel travel. Taken from Camburg's race link kits, they also supply delrin “wobble stoppers” that keep the lower arms positioned correctly throughout the suspension cycle. Adding Camburg's trailing arm kit to your Bronco is an easy bolt-on project that will make a significant improvement for off-road use and includes all the necessary hardware. VEHICLE FITMENT: 2021-Current Ford BroncoKEY FEATURES:

WHAT'S INCLUDED:

| Designed to maintain factory alignment specs on vehicles with 1.5"-3" lift kits. 4130 chromoly tubular upper control arms are 100% bolt on and hand crafted in the U.S.A. The uniball cup placement is moved to correct the caster angle that is lost with aftermarket lift kits. Vehicles that have an increased ride height are harder to align. The added caster reduces the darting or wandering in the vehicles steering and helps retain the factory alignment specifications. 1" I.D. uniballs feature a heat-treated stainless-steel ball & heat-treated stainless-steel race for maximum corrosion resistance and component longevity. These uniballs also feature a military grade PTFE woven fabric liner that helps prevent noise and reduce maintenance. CNC tapered spindle adapters convert the factory ball joint to a 1" uniball for easy installation. Custom profile upper and lower hi-misalignment spacers are machined from 17-4 stainless-steel to maximize strength and wheel travel. Urethane bushings reduce deflection compared to stock rubber bushings. Control arm pivots include zerk fittings to grease the bushings and inner sleeves without disassembly. 3 stage powder coat process includes a durable clear coat to provide a long-lasting finish. Complete grade 8 hardware kit is included. | SPECIFICATIONS

PRODUCT OVERVIEWWhen lifting your truck, the stock upper arms become the limiting factor and hold back your suspensions performance. The Camburg upper arms address these issues and more. Replacing the stock ball-joint with a larger 1.25 uni-ball bearing you're able to gain wheel travel with a part that is considerably stronger and will last longer under extreme conditions. We build more caster and change the camber curve to correct geometry so the vehicle aligns correctly and improves driving characteristics and handling. Our design incorporates a billet aluminum cover for the top of the uniball to keep dirt and other contaminants from working their way into the uniball. This cap is a slight press-fit and uses an o-ring seal. Using the latest CAD/CAM engineering software we design these arms to the strictest standards using our FARO laser scan arm to model the OEM parts and frames. Manufactured in-house, we have the tubes CNC laser cut and bent, then are MIG welded in precision fixtures before sending out to be sandblasted and powder-coated. Our in-house CNC machine shop makes all the machined parts including the uniball mis-alignment spacers from heat-treated stainless steel. We pride ourselves in producing the best parts available under our own roof and control. Notes: With so many variables of wheel sizes, offset/backspacing, tire sizes, brands and styles, the amount of lift and specific suspension components, etc., you may need to trim the plastic inner fenders, sheet metal, etc. to eliminate tire rubbing. 20" OEM wheels & tires and 18" OEM wheels with larger tires than stock will not work with this suspension system "as is" and would require hub-centric wheel spacers. | ||||||||||||||||||||||||

| Content | Top Features and Benefits

|

| ||||||||||||||||||||||||||||

| Weight | 9 كيلوجرام | 10 كيلوجرام | 10 كيلوجرام | 15 كيلوجرام | 10 كيلوجرام | 10 كيلوجرام | ||||||||||||||||||||||||

| Dimensions | 38 × 37 × 18 سنتيميتر | 50 × 32 × 19 سنتيميتر | 40 × 17 × 31 سنتيميتر | 84 × 22 × 14 سنتيميتر | 40 × 40 × 16 سنتيميتر | 38 × 37 × 18 سنتيميتر | ||||||||||||||||||||||||

| Additional information |

|

|

|

|

|

|

المراجعات

لا توجد مراجعات بعد.